China fiber optic Factory

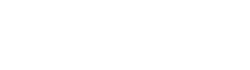

Fiber Optic Splice Trays

Fiber Fusion Splice Trays Manufacturer, Direct Sales from Factory

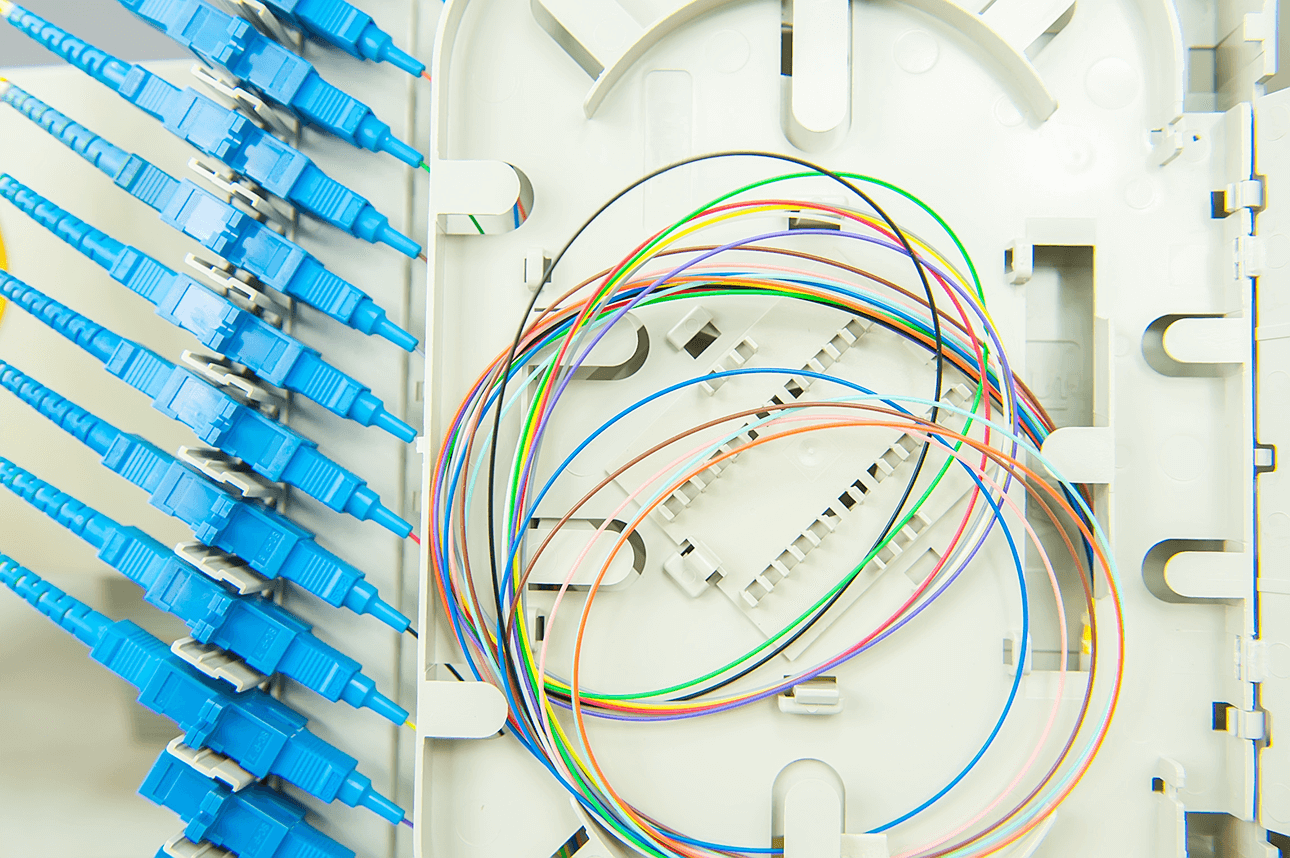

DATA CENTER CABLING

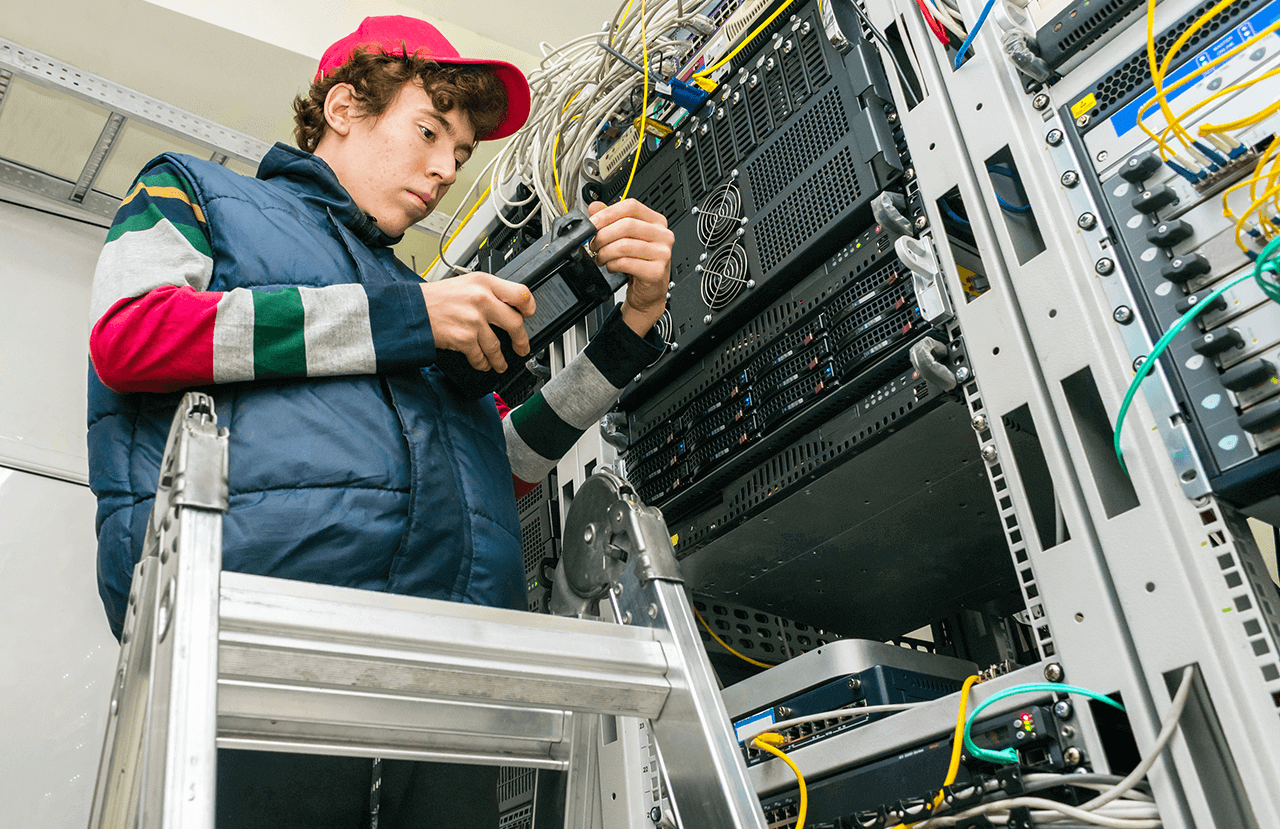

fiber to the home

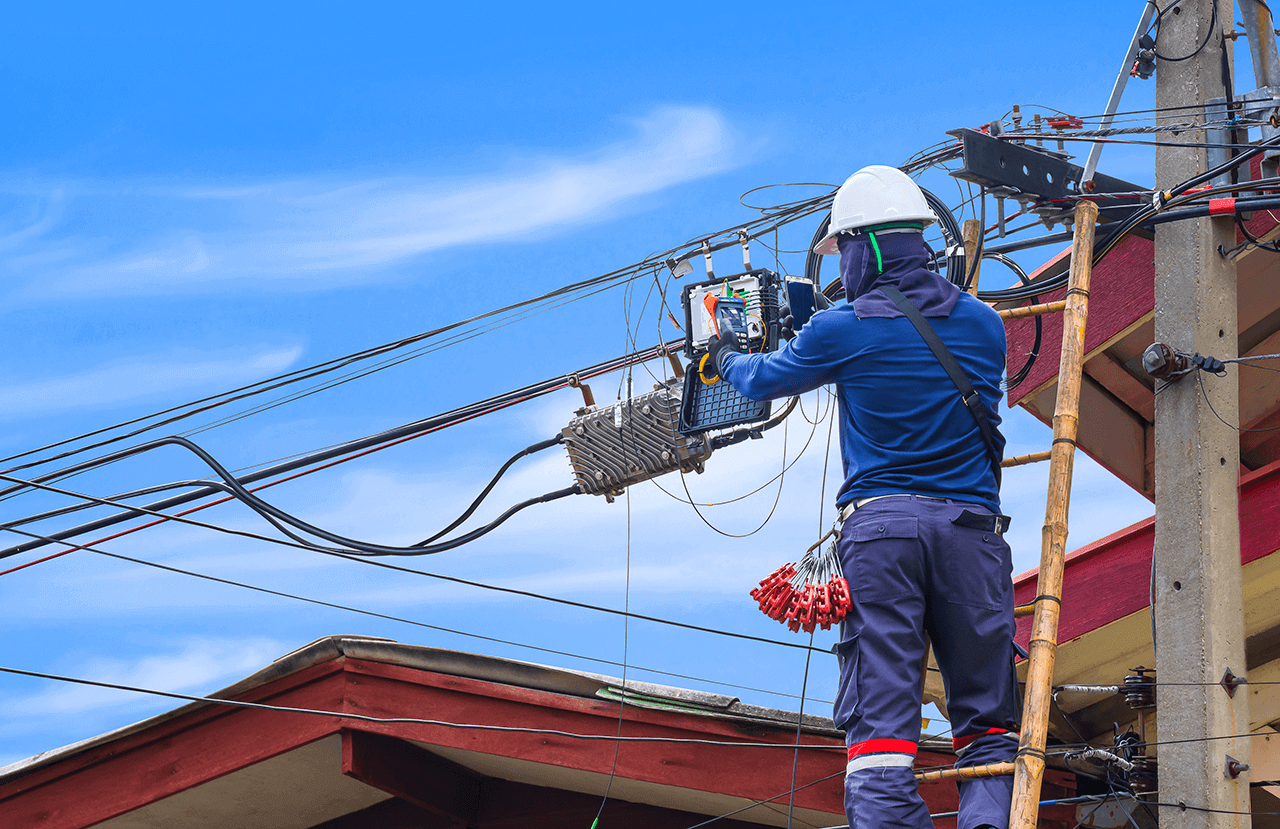

fiber to the antenna

Splicing 250 µm Fiber in a Splice Tray for Rack-Mount Housings

How to Splice Fiber Optic Patch Panel 48 Core

Optical Fiber Cable splicing and Routing

Optical fiber(48) FDMS TERMINATION

A fiber optic splice tray is a type of device used to organize and protect the splices, or connections, between fiber optic cables. It is typically made of a durable material such as plastic or metal and is designed to hold one or more splice holders, which are used to hold and align the fibers as they are spliced together. Huihongfiber splice trays are used in a variety of applications, including telecommunications, cable television, and data centers, to help ensure that the splices are secure and protected from damage. They are also used to organize and manage the fibers within a fiber optic cable plant, making it easier to maintain and troubleshoot the system.

To use a fiber optic splice tray with splice closures, you will need to follow these steps:

1.First, prepare the fiber optic cables for splicing by stripping away a portion of the outer jacket and the strength members, leaving the bare fibers exposed.

2.Next, clean the fibers to remove any dirt or contaminants that could affect the quality of the splice. This is typically done using a fiber optic cleaning kit.

3.Place the fibers into the splice tray, aligning them according to the prescribed splicing pattern.

4.Use the splice holders within the tray to hold the fibers in place as you splice them together. There are several different methods for splicing fibers, such as fusion splicing or mechanical splicing, but the general process involves aligning the fibers and then permanently joining them together.

5.Once the fibers are spliced, you can use a fiber optic splice closure to protect and seal the splices. These closures are typically made of a durable material such as plastic or metal and are designed to enclose and protect the splices from environmental factors such as moisture and temperature changes.

6.To use the splice closure, you will need to follow the manufacturer’s instructions for sealing the closure around the splice tray. This may involve using mechanical fasteners or adhesives to seal the closure shut.

7.Once the splice closure is in place, you can install the splice tray and closure into the desired location within your fiber optic cable plant.

To use splice sleeves in a fiber optic splice tray, you will need to follow these steps:

1.First, prepare the fiber optic cables for splicing by stripping away a portion of the outer jacket and the strength members, leaving the bare fibers exposed.

2.Next, clean the fibers to remove any dirt or contaminants that could affect the quality of the splice. This is typically done using a fiber optic cleaning kit.

3.Place the fibers into the splice tray, aligning them according to the prescribed splicing pattern.

4.Use the splice holders within the tray to hold the fibers in place as you splice them together. There are several different methods for splicing fibers, such as fusion splicing or mechanical splicing, but the general process involves aligning the fibers and then permanently joining them together.

5.Once the fibers are spliced, you can use splice sleeves to protect and seal the splices. Splice sleeves are typically made of a durable material such as heat shrinkable plastic or metal and are designed to enclose and protect the splices from environmental factors such as moisture and temperature changes.

6.To use the splice sleeves, you will need to follow the manufacturer’s instructions for installing the sleeves around the splices. This may involve heating the sleeves with a heat gun or using a mechanical fastener to secure them in place.

7.Once the splice sleeves are in place, you can install the splice tray and sleeves into the desired location within your fiber optic cable plant.

Thank you for your inquiry

There are several different types of fiber optic splice trays from huihongfiber, each of which is designed for specific applications and environments. Here are a few examples: 1.Single fusion splice trays: These trays are designed for splicing a small number of fibers together, typically up to 12 fibers. They are often used in telecom and data center applications where only a few fibers need to be spliced together. 2.Mass fusion splice trays: These trays are designed for splicing a larger number of fibers together, typically more than 12 fibers. They are often used in long-haul telecom and cable TV applications where many fibers need to be spliced together. 3.Heat shrink splice trays: These trays are designed for use with mechanical splicing, which involves aligning the fibers and holding them in place with a mechanical splice connector. The tray is then sealed with a heat shrink sleeve to protect the splices. 4.Cold shrink splice trays: These trays are similar to heat shrink splice trays, but they use a cold shrink sleeve instead of a heat shrink sleeve to seal the splices. This can be useful in applications where heat shrink sleeves are not suitable.5.Field installable splice trays: These trays are designed to be easily installed in the field, making them a convenient choice for use in outdoor or remote locations. They often have a compact design and may be equipped with features such as weatherproofing to protect the splices from environmental factors.